Undertaking a COVID-19 Risk Assessment for your workplace

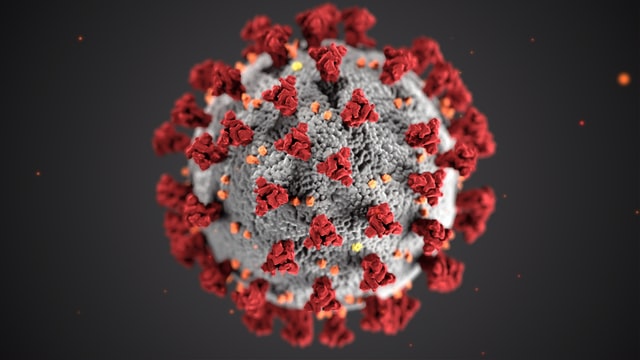

Have you undertaken a current risk assessment to identify the risks associated with exposure to COVID-19 in your workplace? Safe Work Australia has published a downloadable checklist you can follow with the key considerations for identifying risks and control...

7 tips for keeping your remote working team safe and engaged

What does work’ look like for you and your team in this current situation? If your team is working remotely or combining work in the office with work from home, there may be a lack of certainty about when we may all be able to return to work as we knew it, and...

Workplace Manslaughter becomes law in Victoria on July 1st 2020

Victoria has made Workplace Manslaughter a criminal offence and will now have the highest safety fine in the country with maximum penalties of $16.5m and 20 years jail. Victoria is the third state after ACT and Queensland to legislate to make Workplace Manslaughter a...